Unique cable and junction protection boxes are made from reinforced concrete and can be installed in minutes. The one-piece construction design provides easy access for cable jointing and maintenance.

Unique cable and junction protection boxes are made from reinforced concrete and can be installed in minutes. The one-piece construction design provides easy access for cable jointing and maintenance.

Communications boxes are mainly used in infrastructure works to include airports, railway projects, roads and housing developments. Cable pit chambers and other units for street lighting are also available in different sizes.

General Comms Box Features

- Reinforced concrete walls

- Integrated reinforced base*

- Base incorporating sump*

- Splayed base to aid stability*

- Preformed cable entry points

- Easily manoeuvred with lifting eyes

- Ironmongery fitted^

- Suitable for up to 30units HB loading

- Plastic encapsulated steps fitted*^

- Complementary lids are available from good builders merchants

- Bespoke duct arrangements available on request

*Comms J4 has no base, sump or steps

^Comms DP has no ironmongery or steps fitted

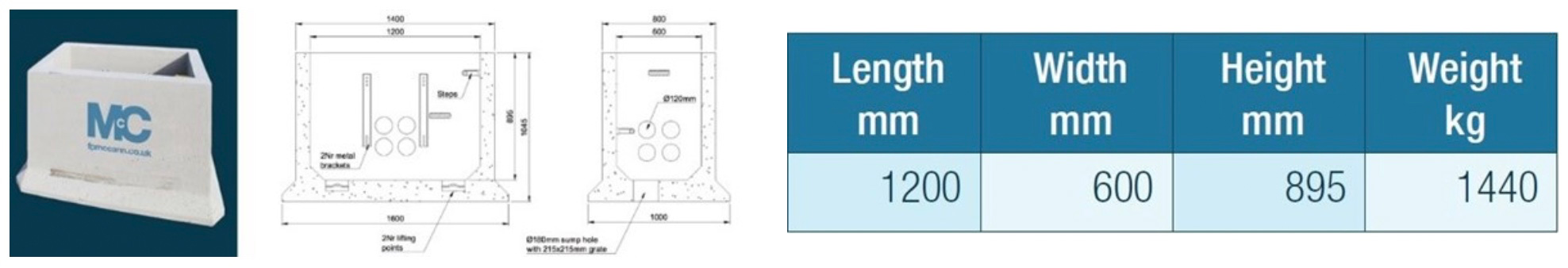

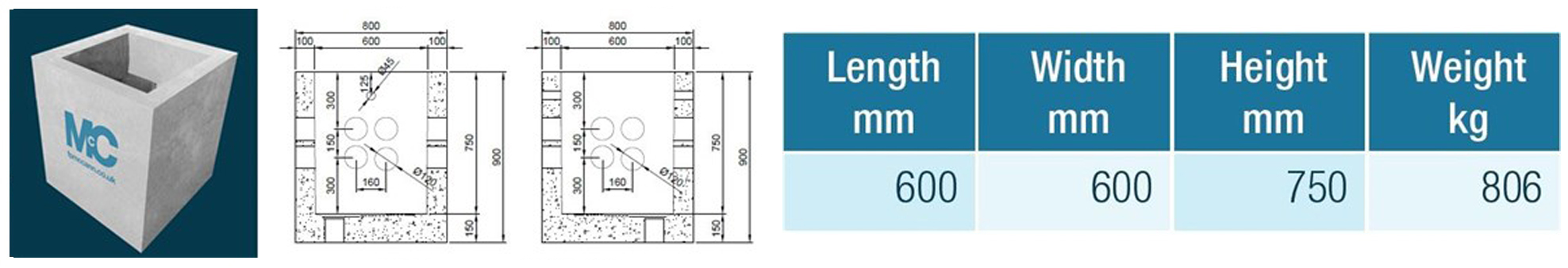

Comms C2

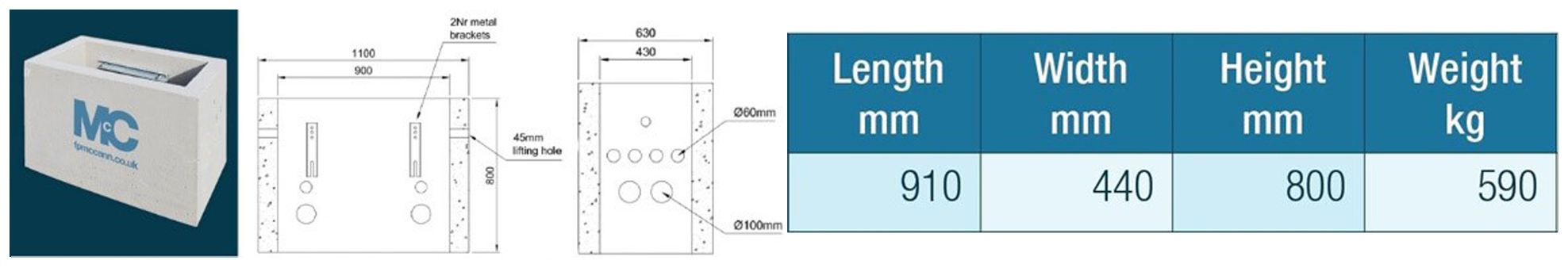

Comms J4

A major innovation, Comms J4 is a unique one-piece unit manufactured with reinforcements, overcoming the self-assembly problem that is associated with other manufactured units.

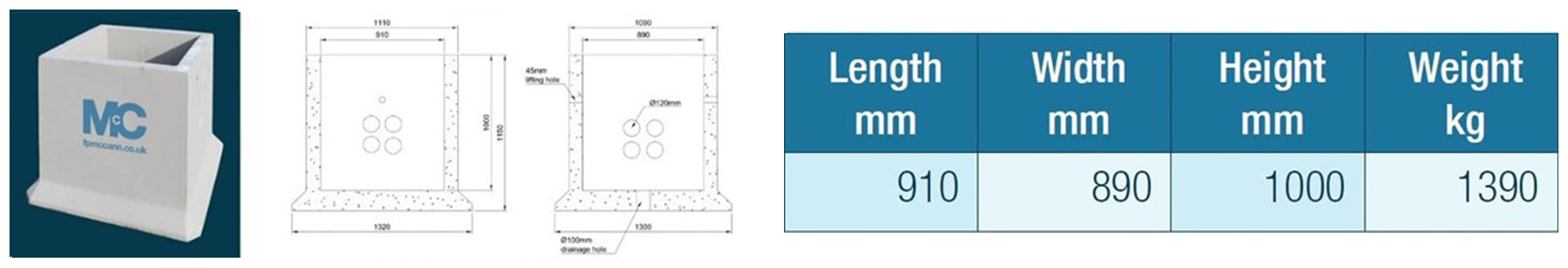

Comms DP

Comms MCX

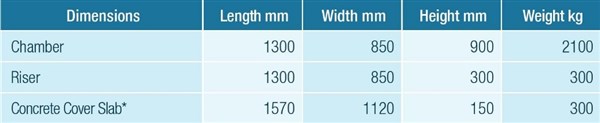

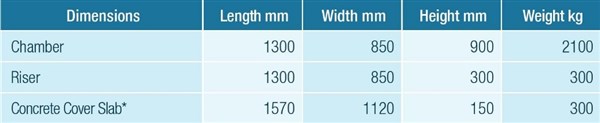

- Highway construction details Comms MCX compliant

- Complimentary reinforced concrete riser and cover slab available from FP McCann

Comms MCX

- Highway construction details Comms MCX compliant

- Complimentary reinforced concrete riser and cover slab available from FP McCann

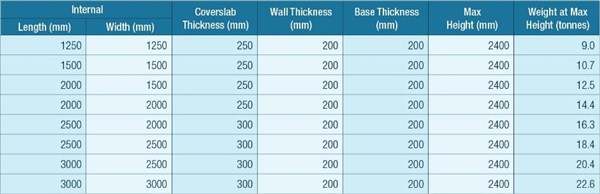

Multi-Purpose Communication Chamber

FP McCann’s precast concrete MLSC multi-purpose communication chambers can be adapted to suit any site requirements. Their flexible design means that they can be factory fitted with duct couplers, step irons, sump units and rebated walls, as required. Multi-purpose communication chambers can be supplied to suit any loading requirements including up to F900+ for airports and similar heavy-duty applications.

Product features

- Available in a large range of sizes from 1250mm x 1250mm to 3000mm x 3000mm

- Available in heights up to 2400mm

- Riser units and cover slabs available

- Suitable for a variety of applications especially for the energy and water industries

- Heavy-duty loading

- Easy access for maintenance

Cast-In Items

If required, the chambers can be delivered with pre-fitted:

- Steps

- Ladders

- Duct Couplers

- Sumps

- Recesses for beam

- Rebates for lids

- Earthing Rods

- Starter Bars

Standard Sizes

Units can be poured in any increment of 100mm from 400mm up to a maximum single unit height of 2400mm internal.

A two or more piece solution is also available if the depth required is greater than 2400mm or if there are on-site weight restrictions that need to be met.

Additional Products

Hydraulically pressed road kerbs

Hydraulically pressed paving flags

Road gullies and gratings

Manhole rings, cover slabs and ductile iron covers

Fire and Blast Walls

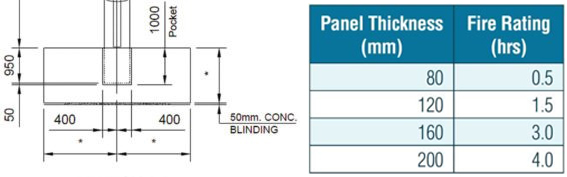

FP McCann manufactures two types of prestressed panels that are ideal for both fire and blast walling.

With the choice of vertical cantilever panels or horizontal panels and columns, fire and blast walls are designed to contain a fire from 30 minutes up to 4 hours, depending on the thickness of the panel. Rapid installation is possible due to the tongue and groove joints. Standard column sections are 500mm x 700mm, with a made-to-order height to customer requirements. Fire walls and columns can be manufactured to the clients’ design or an FP McCann design.

Key features and benefits:

- Vertical Cantilever Panel Fire Walls

- Overall wall heights of up to 7 metres can be achieved

- The panels are designed to be cast into a foundation and FP McCann can supply cradles to assist with this method of installation

Horizontal Panel Fire Walls

- Overall wall heights of up to 10 metres can be achieved

- Panels slot between precast columns and are embedded into the ground via preformed pockets which are then grouted into position using high-strength grout

- It negates the need for a full-length trench to be excavated and concreted, instead favouring easily formable localised pockets at specific centres

Precast Pit Solutions

FP McCann’s precast bespoke pit solutions provide a real alternative to in-situ built pits.

Most airfield projects require the construction of large concrete pits for the main electrical and communication installations. Traditionally, due to their size, these have been constructed in-situ. A modular concrete design has been developed which is factory produced and then assembled on site.

This whole approach has produced a solution which has made a significant and sustainable contribution towards reducing the impact of construction works on the airport environment by reducing time spent on-site, runway possessions and noise.

The end product is of consistently high quality and has the added value of being easier to maintain and alter in the future.

Why an off-site solution

This reduction impacts the number of traffic deliveries to site therefore reducing site storage and site waste. It also eliminates several variables thereby improving programme reliability.

Flexible design

The design of the pits incorporates specially formed plastic sleeves which contain built-in stoppers. The collars are placed in a cluster arrangement avoiding the need to know exactly where future cable runs are. Once a cable location is known, the built-in stopper, within the plastic sleeve can be easily removed. The added benefit of the built-in stopper is that during installation and throughout its life, water ingress through the ducts is prevented. There are many other benefits some of which are listed below:

Where large repetition exists FP McCann can develop a pit solution to suit the specific needs of the client. Typically these could provide high-quality infrastructure for utility companies where large numbers of standard pits are required and where site conditions and constraints require a quick build time.

Drawpits

Part of our StormChamber™ multipurpose chamber range, FP McCann’s draw pits can be adapted to suit any site requirements. Their flexible design means that they can be factory fitted with duct couplers, step irons, sump units, rebated walls and ring beam units, as required.

Drawpits can be supplied to suit any loading requirements such as F900+ for airports and similar heavy-duty applications.

Benefits of Precast Concrete Pits

- 95% reduction in site manhours for pit construction

- 85% reduction in the on-site construction programme

- 55% reduction in lorry movements for deliveries

- Virtual elimination of on-site waste

- Elimination of the need for confined space working

- Significant reduction in site noise

- Provision of a consistently high-quality product

- Product designed for future alterations

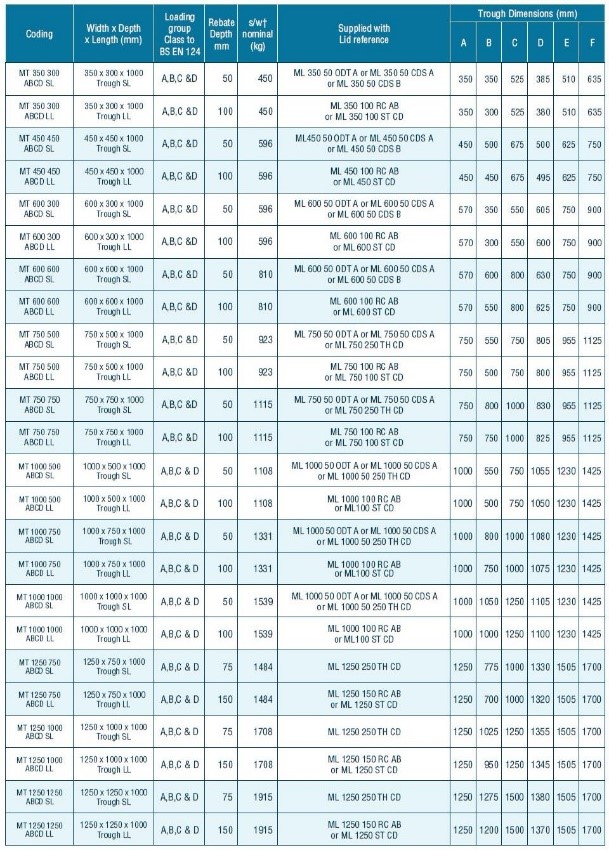

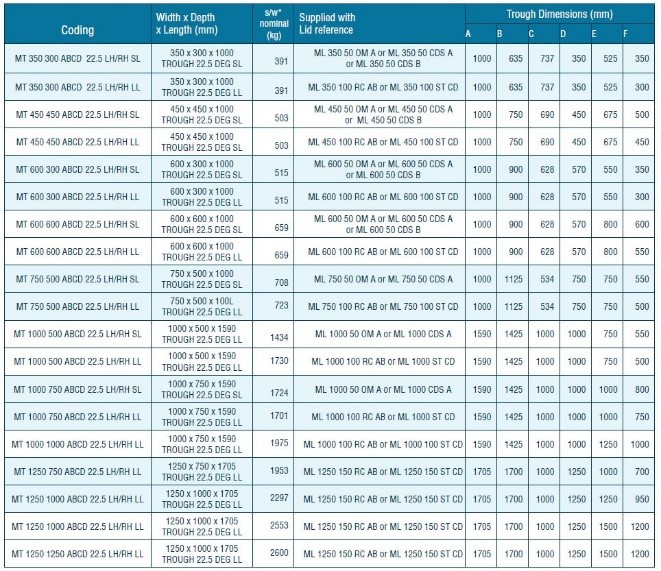

Cable Troughs – Straight Units

FP McCann’s cable trough and service ducts are designed and manufactured to comply with loading criteria as set out in accordance with BS EN 1433 (Troughs) and BS EN 124 (Lids).

All standard cable troughs are one metre long. Two-metre units are available on a made-to-order basis. All operations are conducted in accordance with FP McCann’s quality management system, accredited to BS EN ISO 9001.

Product Benefits

FP McCann’s service duct and trough systems have many advantages:

- Can house high-pressure steam and water pipes

- Applicable to power and telecom cables, as well as pipes for liquids and gas

- Chemically-resistant concrete

- Services buried at depth are unexposed to weather changes ie. freezing or overheating

- High-strength load-bearing units

- Easy access for repairs, jointing or new service additions

- Whole life costs of precast concrete are lower than other forms of service trench construction

- Non-conductive to electricity

- Bespoke units can be made to specification

- No concrete surround required

Product Applications

- Substations

- Power stations

- Converter stations

- Wind farms

- Gas compressor plants

- Energy from waste plants

- Batter storage plants

- Biomass plants

- Waste treatment plants

- Oil, gas and fuel pipelines

- Hospitals

- Commercial infrastructure

- Prisons

- MOD

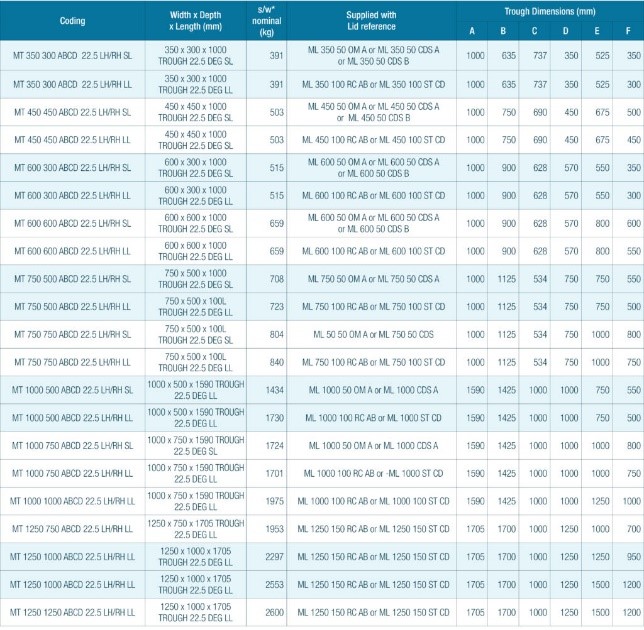

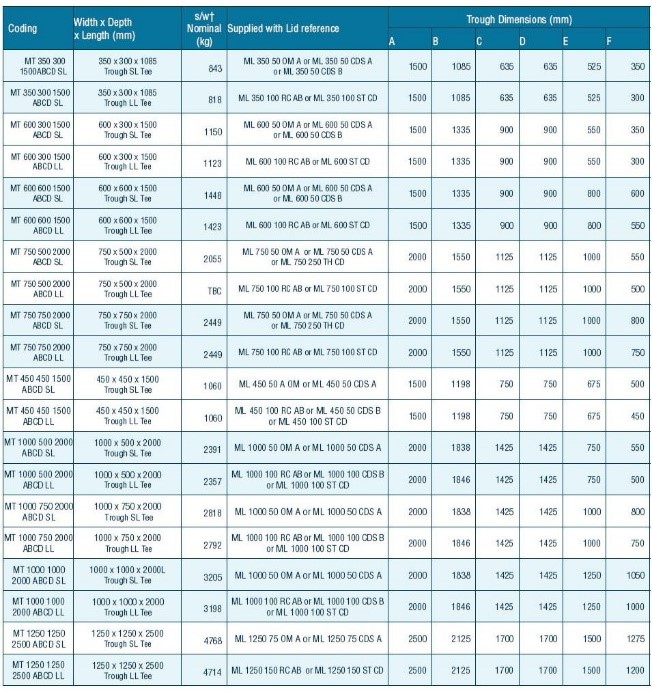

Cable Troughs – Corner, Angled & Tee Units

Units to form changes in troughing direction are available in some sizes, maybe cast in-situ or formed from standard units on site. However, care should be taken that such features are suitable for the anticipated trafficking.

Bespoke designs to suit particular conditions can be provided. Corner, tee and specific angled cable trough units are usually available ex-stock. Please contact Gavin Coleman from our sales office to discuss availability.

The units incorporate galvanised steel angles to support lids where necessary and have curved inner corners to allow ease of cable laying.

*Corner Unit Trough Dimensions

*Tee Unit Trough Dimensions

*Angled Unit Trough Dimensions

*All dimensions contained within these table are nominal and do not take into account manufacturing tolerances.

† maximum self-weight = nominal self + 5%, which should be used to size lifting equipment. Additional sizes are available upon request.

Other angled units, including 11.25º, 15º and 30º are available on request

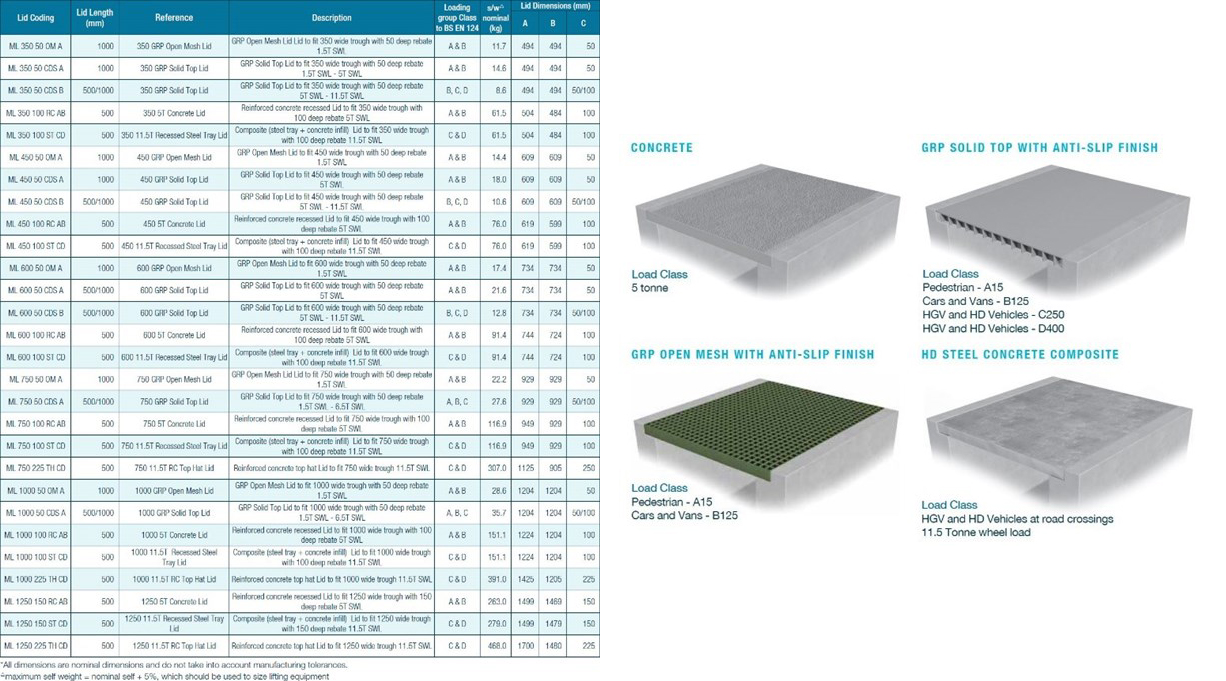

Cable Trough Lids

FP McCann provides three types of flush fitting cable trough lids/covers supplied in either reinforced precast concrete, GRP composite or steel tray. All lids are rated in accordance with the loading groups specified in BS EN 124.

All concrete and steel composite covers have cast-in lifting sockets. If required, GRP covers can also have lifting slots.

Locking devices are available for lids to give added security. Sealed units prevent water ingress.