The Ridgidrain Advanced Drainage System is the complete technical and commercial answer to all non-pressure, surface and sub-surface water drainage applications.

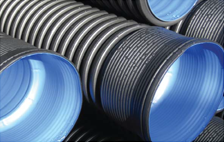

Polypipe Civils Twin Wall Pipes

Ridgidrain pipes have been installed for highway, rail and airport infrastructure projects as a direct alternative to concrete and clayware pipes. The Ridgidrain system was the first drainage product in the market to achieve the new HAPAS specification (Highways Authorities Product Approval Scheme) issued by the BBA.

Pipes and fittings from 100mm up to 600mm diameter are available in unperforated, half perforated and fully perforated 6m lengths.

Pipes and fittings in diameters of 750mm and above are now available as part of the Ridgistorm-XL large diameter range.

Ridgidrain Storm Pipe

The Ridgidrain Advanced Drainage System is the complete technical and commercial answer to all non-pressure, surface and sub-surface water drainage applications. Ridgidrain pipes have been installed for highway, rail and airport infrastructure projects as a direct alternative to concrete and clayware pipes. The Ridgidrain system was the first drainage product in the market to achieve the new HAPAS specification (Highways Authorities Product Approval Scheme) issued by the BBA.

Pipes and fittings in diameters of 750mm and above are now available as part of the Ridgistorm-XL large diameter range.

Key features and benefits

- BBA Approved (750 and 900mm as a sealed system)

- Light weight for ease of handling and installation

- 100% recyclable after its 100 year design life

- Manufactured in accordance with BS EN 13476

- Designed in accordance with BS EN 12-95

- Ideal for use as large-scale attenuation system

- Able to withstand ground movement without leakage

- Superior hydraulic performance achieved through smooth bore 750mm, 900mm, 1050mm, 1200mm, 1500mm, 1800mm and 2100mm diameters

- 6m lengths as standard

- Excellent resistance to sulphate and chemical attack

- Longer pipe lengths for improved pipeline integrity and fewer joints

- Unique patented electro-fusion jointing system

- Excellent load bearing capability

- Due to its light weight less plant machinery is required on-site reducing installation costs

- Water Company Approved